Published on: Saturday, 28 June 2025 ● 5 Min Read

The Impact of Increasing Demand for Lightweight Aerospace Components on Advancements in High-Precision Tooling within India's Aerospace Manufacturing Sector

Kennametal’s portfolio spans the full spectrum of aerospace manufacturing needs—from engines and structures to landing gear, composites, and other critical components. As this industry increasingly adopts advanced materials such as CFRP, titanium, aluminum, and hard alloys to reduce aircraft weight and enhance fuel efficiency, the demand for tooling solutions capable of machining these materials with precision and consistency are on the rise.

These advanced materials, while providing several benefits, present certain machining challenges, as they require tight tolerances, superior surface finishes, and high thermal stability. To address these demands, aerospace manufacturers are turning to tooling solutions that deliver not only precision and high metal removal rates but also faster cutting speeds and greater flexibility—all while maintaining excellent tool life.

This is where Kennametal’s deep-rooted expertise in materials science and tooling innovation comes into play. For example, our HARVI™ IV Solid Carbide End Mills were specifically engineered for machining titanium—one of the toughest materials in aerospace. This tool delivers exceptional productivity, consistently removing up to twenty cubic inches of titanium per minute, with a tool life exceeding one hour.

Similarly, products such as the KSEM™ modular drills and 7792VX high-feed milling cutters enable efficient material removal while maintaining tight tolerances, crucial for structural components like ribs, panels, and landing gear.

Over the years, Kennametal has developed a comprehensive portfolio of advanced tooling solutions that empower the aerospace industry to innovate and build better every day.

Tooling Innovations Tackling Thermal Expansion, Tool Wear, and Vibration to Achieve Micron-Level Precision in Aerospace Manufacturing in India

Aerospace machining demands innovative solutions that can withstand extreme conditions while delivering precision and durability.

Superhard materials such as Cubic Boron Nitride (CBN) and Polycrystalline Diamond (PCD) offer excellent wear resistance and maintain sharp cutting edges at high temperatures. Kennametal’s PCD-tipped tools and KCU series CBN inserts are designed specifically for high-performance aerospace machining. Coatings such as TiAlN and AlTiN enhance tool life by improving thermal stability and reducing friction. Kennametal’s Beyond™ Evolution™ ALTiN-coated inserts are a strong example of this innovation in action.

Tool geometry also plays a critical role. Features like lower approach angles, variable helix angles, and larger core diameters help reduce cutting forces and vibration. Kennametal’s HARVI Ultra 8X Solid Carbide End Mills exemplify this, offering stability and performance in titanium and nickel-based alloys. Tools with internal coolant channels—like the KenTIP™ FS modular drill system—enable efficient chip evacuation and cooling, essential for dimensional consistency.

Integrating Automation and AI-Driven Machining to Enhance High-Precision Tooling Efficiency in Aerospace Manufacturing

The aerospace industry has been witnessing a rapid adoption of digital engineering, IoT and AI. Intelligent systems are being integrated throughout the aircraft lifecycle by OEMs and tier suppliers to cope with ever increasing component manufacturing complexities. One of the key areas where we’re seeing transformative impact is digital twin technology. By creating virtual models of aerospace components, machining environments and processes, we can simulate performance, optimize tool paths and predict tool wear before production even begins. This reduces trial-and-error on the shop floor, minimizes downtime and improves first-pass yields—especially critical in high-stakes sectors like aerospace and automotive.

Our IoT-enabled tooling solutions provide real-time data on parameters like temperature, vibration and cutting forces, allowing for predictive maintenance and smarter decision-making. For example, we helped an aerospace manufacturer improve productivity by 50% and achieve significant cost savings while machining Inconel.

Leveraging High-Precision Tooling to Meet International Certification Requirements in Indian Aerospace Manufacturing

To meet stringent global aerospace standards like AS9100 and NADCAP, Indian manufacturers are turning to high-precision tooling solutions that ensure dimensional accuracy, surface integrity, and process repeatability. Given the complexity of working with materials such as CFRP, titanium, aluminum, and hard alloys, it can be challenging to maintain consistency across high-tolerance applications using conventional tooling.

To address this, manufacturers are increasingly adopting advanced tooling systems from global leaders like Kennametal. Solutions such as HARVI Ultra 8X and KOR6™ DT end mills, Beyond Evolution ALTiN-coated inserts, GOdrill™ solid carbide drills, KCU series CBN inserts, PCD-tipped tools, and KenTIP™ FS modular drilling system offer high metal removal rates, thermal resistance, and repeatable performance—critical for qualifying under international certification protocols. These tools are engineered to handle difficult-to-machine alloys while minimizing tool wear and maintaining part integrity.

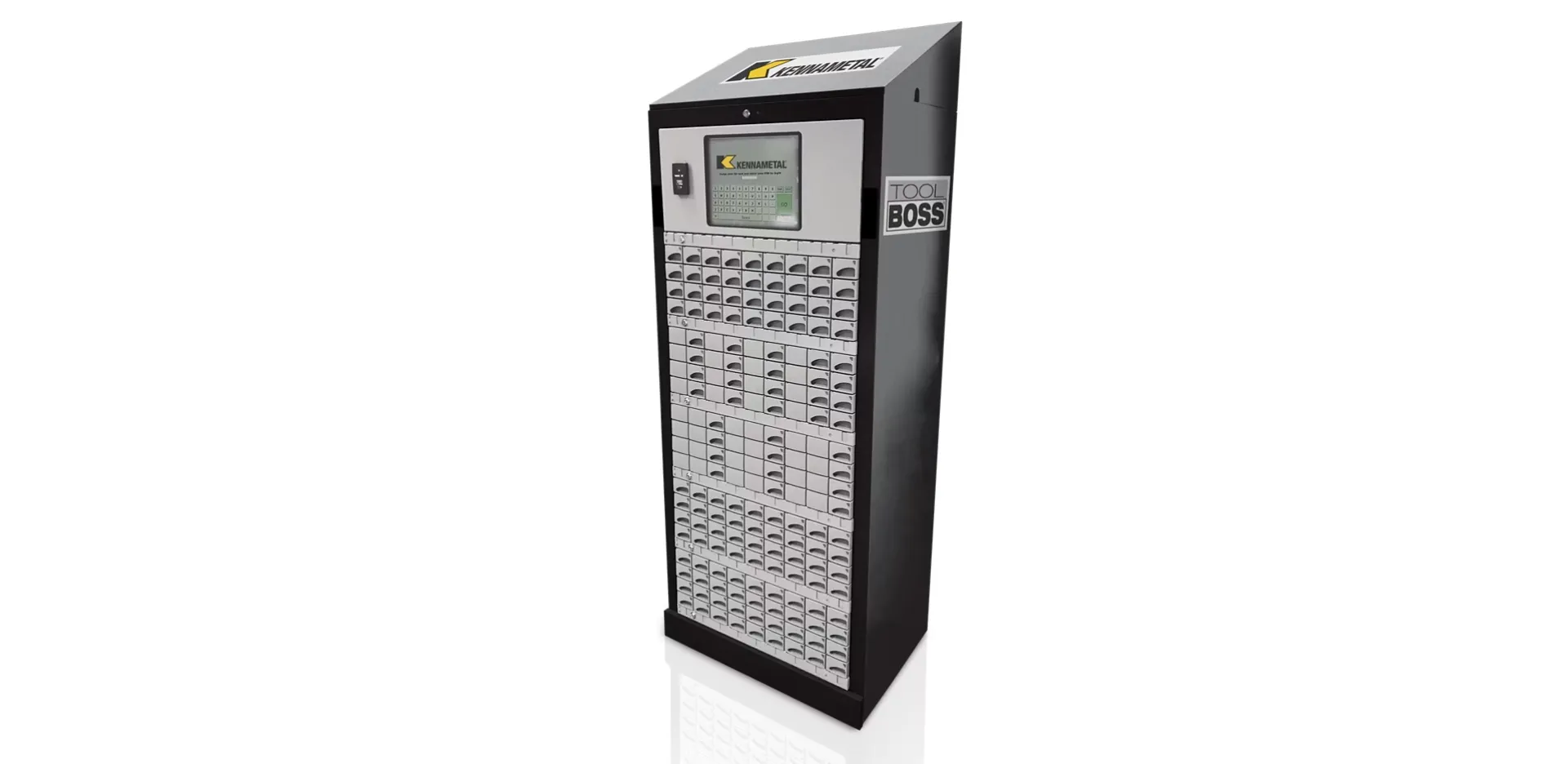

Additionally, digital platforms like Kennametal’s ToolBOSS™ enhance traceability, inventory control, and compliance by offering detailed usage reports and tool lifecycle visibility. This supports not only productivity but also the documentation and process control required for audits and certifications.

Emerging Technologies and Process Innovations Set to Redefine High-Precision Tooling for Aerospace Manufacturing in the Next Five Years

Aerospace manufacturing is continuously evolving—both in the materials used and the processes followed—to meet the growing demand for lighter aircraft, efficient fuel consumption and reduced emissions. In the next five years, high-precision tooling for aerospace manufacturing will be transformed by technologies like IoT-enabled CNC machines, advanced tooling solutions and sustainability.

The integration of IoT-enabled, multi-tasking machines is revolutionizing factory operations enabling OEMs to build factories of the future. Augmented and Virtual Reality are also being adopted for remote machine commissioning, and troubleshooting.

In the coming years, the need for innovative tooling solutions will be paramount to keep pace with the demands of machining advanced aerospace materials, as mentioned earlier. Simultaneously, the industry is increasingly focused on sustainability, with efforts to reduce emissions, noise, and material waste for managing a green product lifecycle.

No comments posted

© 2019 KIVAA Group | All right reserved. www.theindustrial.in

Leave a reply: