Published on: Sunday, 01 October 2023 ● 7 Min Read

In the last decade, liquid lenses have been among the most exciting new technologies emerging in the machine vision industry. These lenses make it possible for a single lens and camera to accomplish what would previously take multiple systems to achieve, providing an extraordinary amount of flexibility in designing machine vision systems. Integrating liquid lenses into imaging systems is an ideal solution for applications requiring rapid focusing, high throughput, and accommodation for depth of field and working distance.

Working principle

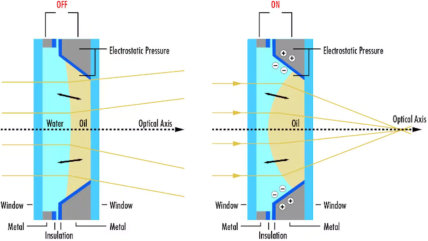

Liquid lenses as a term cover a range of different lens types that use fluid as opposed to traditional glass or plastic lenses and change their curvature upon application of a current or voltage—depending on the type of liquid lens. At any given focal length, a liquid lens generally behaves like a traditional lens, as the material and the curvature determine the optical power in the lens. However, since a liquid lens’s curvature can change, it can effectively act like a near infinite number of lenses, since every adjustment of the curvature changes the focal length. This flexibility can be utilised to drive a working distance change in machine vision lenses.

Most traditional fixed focal length lenses change focus position by moving groups of lens elements together, while keeping the relative element spacing constraint. As an object being imaged moves farther away from the lens, the back focal length (defined as the distance from the back of the lens to the plane of focus) of the lens gets smaller. Conversely, as the distance of the object increases, the back focal length increases. This focusing methodology proves effective when needing to focus the lens once and not touch it again during operation. But with machine vision deploying into more spaces than ever before, and with newer sensor technology pushing the boundaries of system capabilities, additional flexibility is required in the optics. Liquid lenses overcome this limitation of focusability by allowing the lens assembly to focus quickly and accurately, changing its back focal length by adjusting the curvature instead of physically moving parts of the assembly.

In the last decade, liquid lenses have been among the most exciting new technologies emerging in the machine vision industry. These lenses make it possible for a single lens and camera to accomplish what would previously take multiple systems to achieve, providing an extraordinary amount of flexibility in designing machine vision systems. Integrating liquid lenses into imaging systems is an ideal solution for applications requiring rapid focusing, high throughput, and accommodation for depth of field and working distance.

Working principle

Liquid lenses as a term cover a range of different lens types that use fluid as opposed to traditional glass or plastic lenses and change their curvature upon application of a current or voltage—depending on the type of liquid lens. At any given focal length, a liquid lens generally behaves like a traditional lens, as the material and the curvature determine the optical power in the lens. However, since a liquid lens’s curvature can change, it can effectively act like a near infinite number of lenses, since every adjustment of the curvature changes the focal length. This flexibility can be utilised to drive a working distance change in machine vision lenses.

Most traditional fixed focal length lenses change focus position by moving groups of lens elements together, while keeping the relative element spacing constraint. As an object being imaged moves farther away from the lens, the back focal length (defined as the distance from the back of the lens to the plane of focus) of the lens gets smaller. Conversely, as the distance of the object increases, the back focal length increases. This focusing methodology proves effective when needing to focus the lens once and not touch it again during operation. But with machine vision deploying into more spaces than ever before, and with newer sensor technology pushing the boundaries of system capabilities, additional flexibility is required in the optics. Liquid lenses overcome this limitation of focusability by allowing the lens assembly to focus quickly and accurately, changing its back focal length by adjusting the curvature instead of physically moving parts of the assembly.

Integrating the liquid lens

Liquid lenses can be integrated into machine vision optics in several ways, with retrofitting onto the front or the back of the lens or inserting into the middle of existing lenses. While retrofitting can work for many applications, it is also limited in what it can accomplish. Designing the entire lens objective from the ground up around the architecture of the liquid lens represents the optimal liquid lens integration method. Designing a lens in such a way allows advantages such as overcoming depth of field limitations of traditional lenses and speed of changing focus. In traditional lenses, depth of field is limited by f/#: the higher the f/#, the larger the depth of field. Lenses used in logistics-based applications or barcode scanning, for example, often take advantage of the large depth of field associated with a high f/# lens but must be able to image over a large distance. Increasing the f/#, however, has two distinct disadvantages that come with the larger depth of field: loss in overall resolution, and a necessary exposure time increase, since the aperture size has been decreased and less light makes it through the system. Designing an objective with an integrated liquid lens can get around both disadvantages. Since liquid lenses allow incredibly fast (10s of milliseconds) refocusing, a shallow depth of field lens no longer presents a problem. An objective lens with an integrated lens should be designed at as low of an f/# as possible, and do not require a variable iris like traditional machine vision lenses. Additionally, increasing the f/# on an objective with a liquid lens becomes irrelevant since its entire purpose is overcoming depth of field limitations of traditional lenses.

The increased exposure time required when f/# increases also mitigates the speed that the liquid lens can change focus as well. If the exposure must be higher to collect more light at a higher f/#, the liquid lens speed isn’t being used to its full potential. In addition to a fixed aperture, a lack of mechanical adjustment for focusing represents another important feature of objectives built around liquid lenses. Ideally, all focusing should be done by the changes in liquid lens curvature to simplify the focusing process. Retrofitting an objective with a liquid lens may require a mechanical adjustment for focusing, since the system was not initially designed to incorporate a liquid lens. Such an adjustment helps optimise performance at various distances while sacrificing range. However, this also vastly decreases the lens’s ease of use and creates an infinite solution space of planes of focus. This infinite solution space negatively impacts performance repeatability when developing a system with multiple instances. Designing a lens that only focuses via liquid lens and not from mechanical adjustment offers a more straightforward process for lens focusing, and the performance becomes more predictable as well.

Applications

The adaptability, speed, and versatility of liquid lenses make them ideal for a variety of machine vision, life science, measuring and inspection applications. Due to the traditional mechanical layout, standard machine vision lenses struggle to capture sharp and accurate images in high-speed or precise applications that require quick refocusing. High-volume assembly lines require fast, accurate, and precise throughput. Integrating a liquid lens into an inspection system is an optimal, compact, and economical solution when focusing at multiple distances is required. Liquid lenses are an ideal solution for barcode inspection, package sorting, quality control, and rapid automation.

In Microscopy imaging applications, liquid lenses improve and simplify the process of focus stacking. Focus stacking is often required when imaging with high magnification objectives due to their limited depths of field. A liquid lens can quickly and precisely focus to various object planes, therefore speeding up focus stacking. Liquid lenses can be easily integrated into tube lenses or in infinity space within a microscope.

Liquid lenses are often used in ophthalmology, where refraction control and depth of field adjustment is crucial. Standard ophthalmic equipment contains multiple glass lenses used to adjust for the human eye. These lenses can be replaced with a single liquid lens, speeding up the imaging or diagnosis process and decreasing the overall size of ophthalmic equipment such as OCTs and phoropters.

By adding a liquid lens to an unmanned aerial vehicle (UAV) imaging system, image sharpness is quickly maintained across various heights. Liquid lenses are especially advantageous in agricultural inspection and monitoring, geographic information systems, and in surveillance applications.

Applications

The adaptability, speed, and versatility of liquid lenses make them ideal for a variety of machine vision, life science, measuring and inspection applications. Due to the traditional mechanical layout, standard machine vision lenses struggle to capture sharp and accurate images in high-speed or precise applications that require quick refocusing. High-volume assembly lines require fast, accurate, and precise throughput. Integrating a liquid lens into an inspection system is an optimal, compact, and economical solution when focusing at multiple distances is required. Liquid lenses are an ideal solution for barcode inspection, package sorting, quality control, and rapid automation.

In Microscopy imaging applications, liquid lenses improve and simplify the process of focus stacking. Focus stacking is often required when imaging with high magnification objectives due to their limited depths of field. A liquid lens can quickly and precisely focus to various object planes, therefore speeding up focus stacking. Liquid lenses can be easily integrated into tube lenses or in infinity space within a microscope.

Liquid lenses are often used in ophthalmology, where refraction control and depth of field adjustment is crucial. Standard ophthalmic equipment contains multiple glass lenses used to adjust for the human eye. These lenses can be replaced with a single liquid lens, speeding up the imaging or diagnosis process and decreasing the overall size of ophthalmic equipment such as OCTs and phoropters.

By adding a liquid lens to an unmanned aerial vehicle (UAV) imaging system, image sharpness is quickly maintained across various heights. Liquid lenses are especially advantageous in agricultural inspection and monitoring, geographic information systems, and in surveillance applications.

Nicholas Sischka Nicholas Sischka is Manager of Sales Operations of Imaging Business Unit at Edmund Optics' Barrington, NJ, USA office. Specialising in optics for vision systems, Nicholas supports imaging and machine vision customers with application knowledge and design assistance for modification or customisation requirements. Additionally, he has successfully trained EO’s global vision partners on the specifics of how optics interface with cameras and lighting. An accomplished author, Nicholas has written multiple articles on such diverse topics as using optical filters to enhance image contrast and liquid lenses for machine vision. He holds a B.S. in Optical Sciences and Engineering from the University of Arizona, College of Optical Sciences.

Adarsha Sarpangala is Imaging Business Key Account Manager in Edmund Optics India Pvt Ltd, Bengaluru office. He manages the machine vision business of Edmund Optics for the Indian market. Adarsha has around 10 years of experience in the machine vision industry including selection of cameras, lens, lighting and machine vision solutions. For any queries on the articles or machine vision applications he can be contacted on asarpangala@edmundoptics.in

No comments posted

© 2019 KIVAA Group | All right reserved. www.theindustrial.in

Leave a reply: